Products & Services

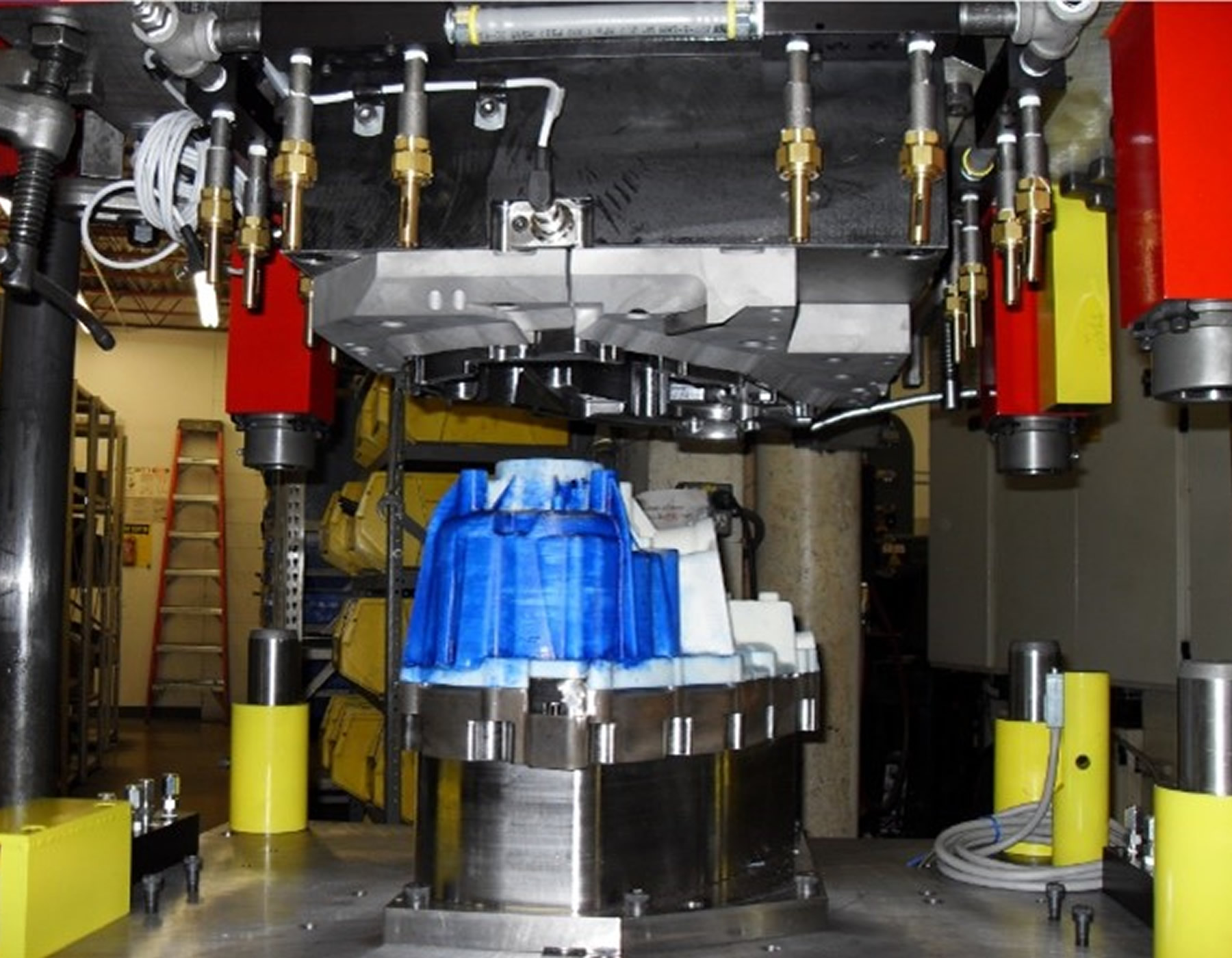

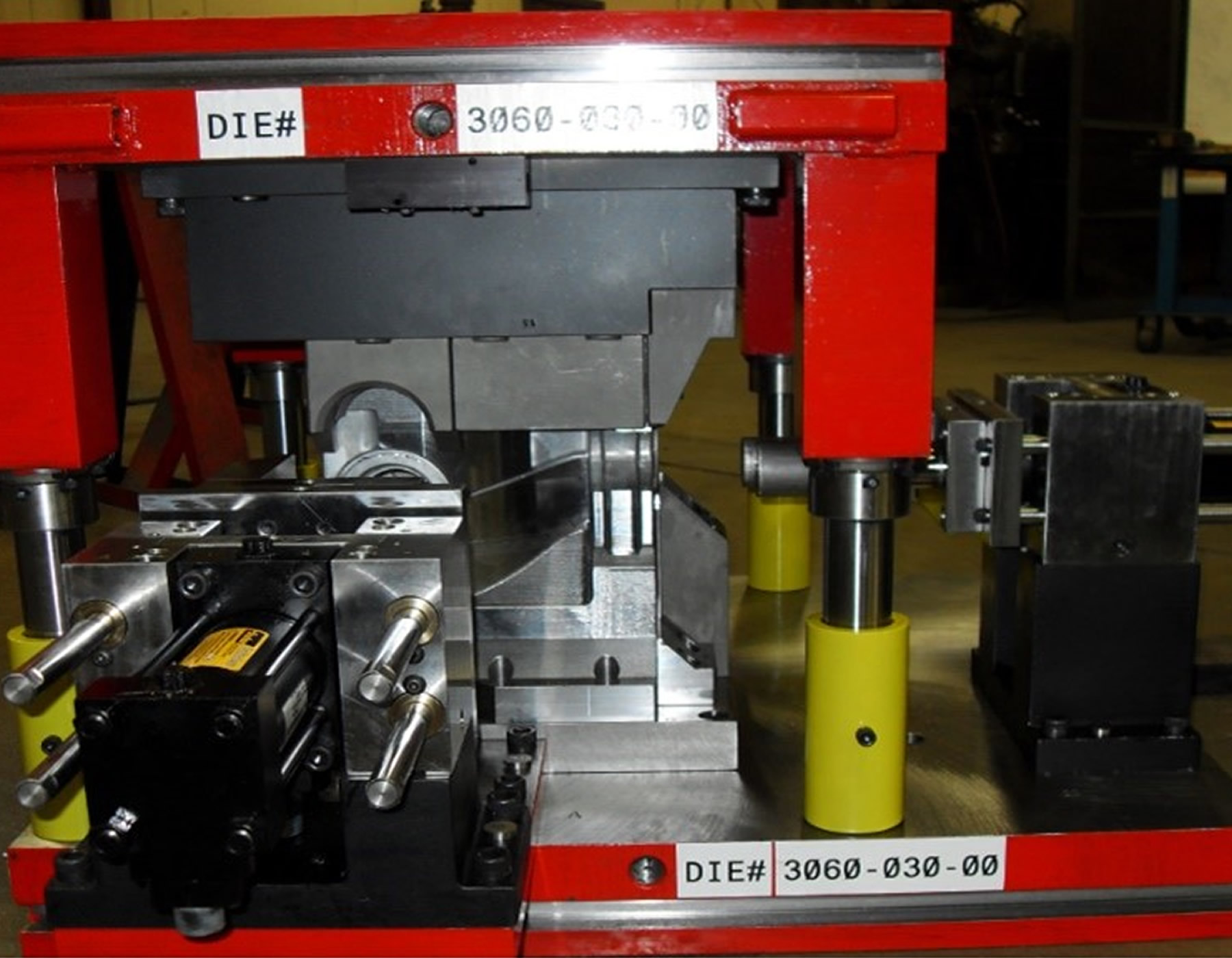

Trim Dies

Our Trim Dies are all Custom Made to fit your product. Whether is a simple part that can be trimmed with a Push-Thru Trim Die or a large complicated part that needs a Double Action Hydraulic Saw Trim Die. We can design and build a trim die to fit whatever your needs are.

Hole Popper

Our ProSpark Hole Popper allows us to pop holes .02 to .125 in steel.

It also pops out broken taps, drill bits and screws out of all types of materials.

Bonding Units

We build Brake Pad Bonding Machines in both 6 and 12 station.

We use a combination of heat and pressure to bond the noise reduction plate to the backing plate.

It is manually loaded and auto unloaded with a conveyor belt.

CCM

Our CMM verifies a parts dimension, which then enables us to reverse engineer that part.

3D Printing

Our 3-D Printer allows us to make proto type parts as well as make a part from your print for you to review or for us to use a model to build your trim die around.

Wire Machines

Our Sodick wire machines allow us to cut shapes out of steel that would not be possible to cut on any other machine, with travels 14 x 20 x 9.5

CNC

Our CNC’s are top of the line Hurco units capable of all shaping all types of steel with travels up to 35” x 65”.

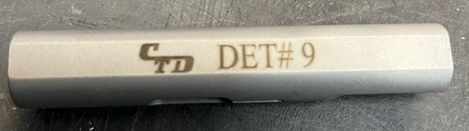

Engraver

We engrave all perishable parts of each trim die. Our Laser engraver can engrave all types of steel, Brass, Aluminum, copper and plastic. The work area is 36 x 24 x 9 so we have plenty of room for larger pieces. We can even engrave your logo and die number on specialty parts.